Table of Contents

- Risk

- EPR

- MOQ & Lead Times

- Leadership

- Customer Health

- Environment

- Cost

- Safe Today, Sorry Tomorrow

- FAQs on Compostable Packaging

- Why you Actually should

At WildKind Packaging, we hear the same objections all the time: compostable packaging is risky, expensive, or too complicated. And sure, if you’d rather cling to the status quo, there are plenty of reasons to avoid it. But here’s the twist: those reasons are exactly what will cost your brand the most in 2025 and beyond. So let’s get into it. Why shouldn’t you do compostable packaging in 2025?

I. Because Risk Is Dangerous

You can’t take a chance. What if regulations change overnight? What if a lawsuit or scandal puts your brand in the “greenwashing” spotlight? In today’s hyper-aware consumer world, being caught using non-compostable, non-certified materials (or worse, misleading claims) can damage your reputation faster than anything else.

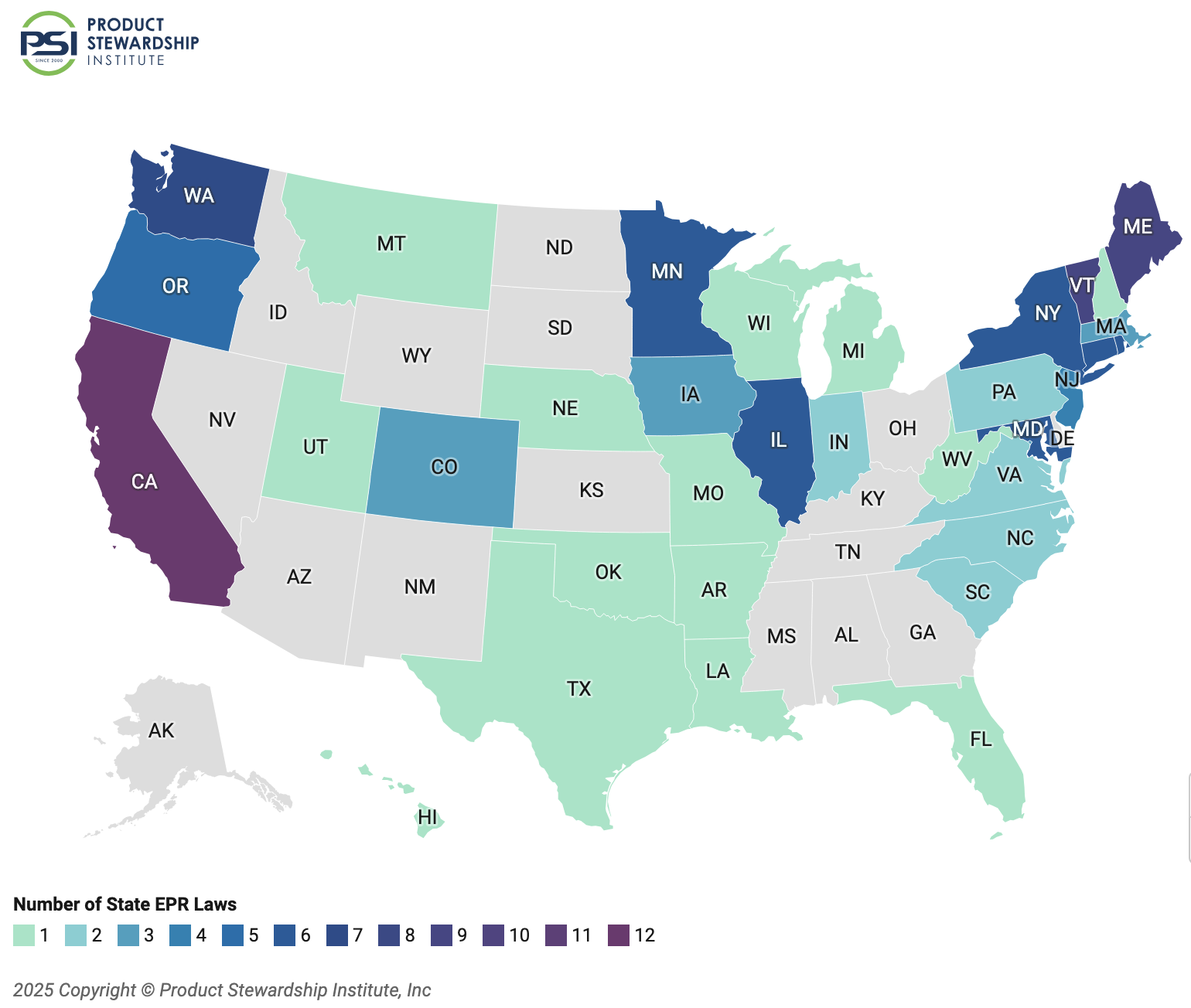

II. Because EPR Will Never Affect Your Business

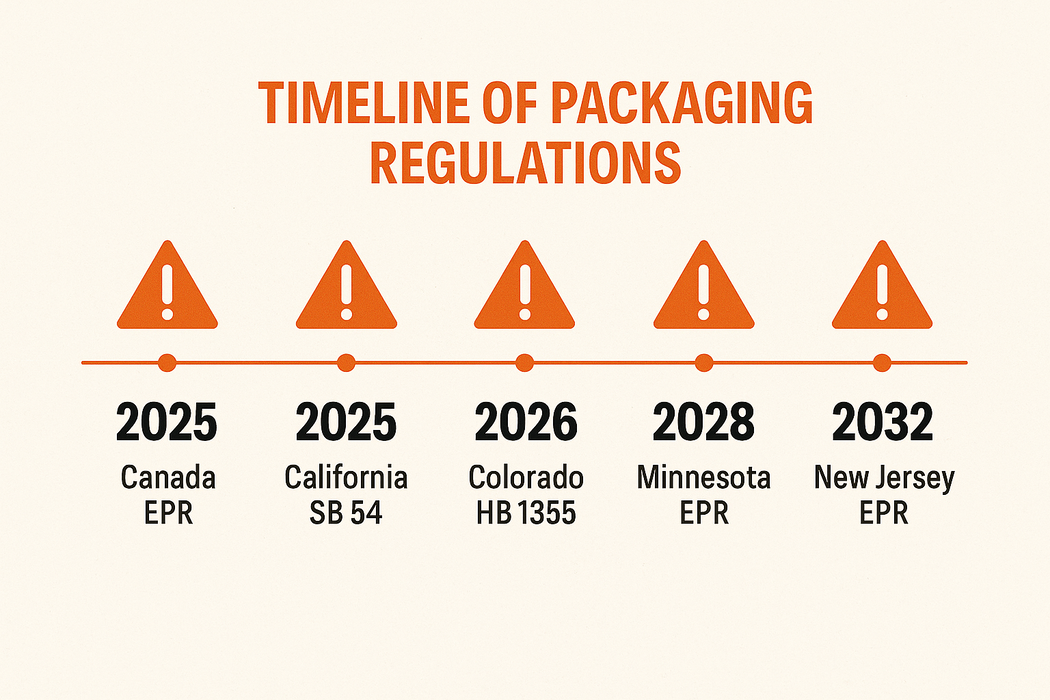

EPR (Extended Producer Responsibility) laws? Not relevant to you… yet. But here’s the thing: many U.S. states already have or are putting EPR packaging laws into effect, with more in the pipeline. (PwC)

If you stick with traditional packaging, you’ll be paying penalties, surcharges, and possibly face bans or restrictions. Compostable and recyclable materials are increasingly factored into EPR fee structures. Ignoring them is like refusing to pay taxes because "they haven’t knocked on my door yet."

“Ignoring EPR is like refusing to pay taxes because they haven’t knocked on your door yet.”

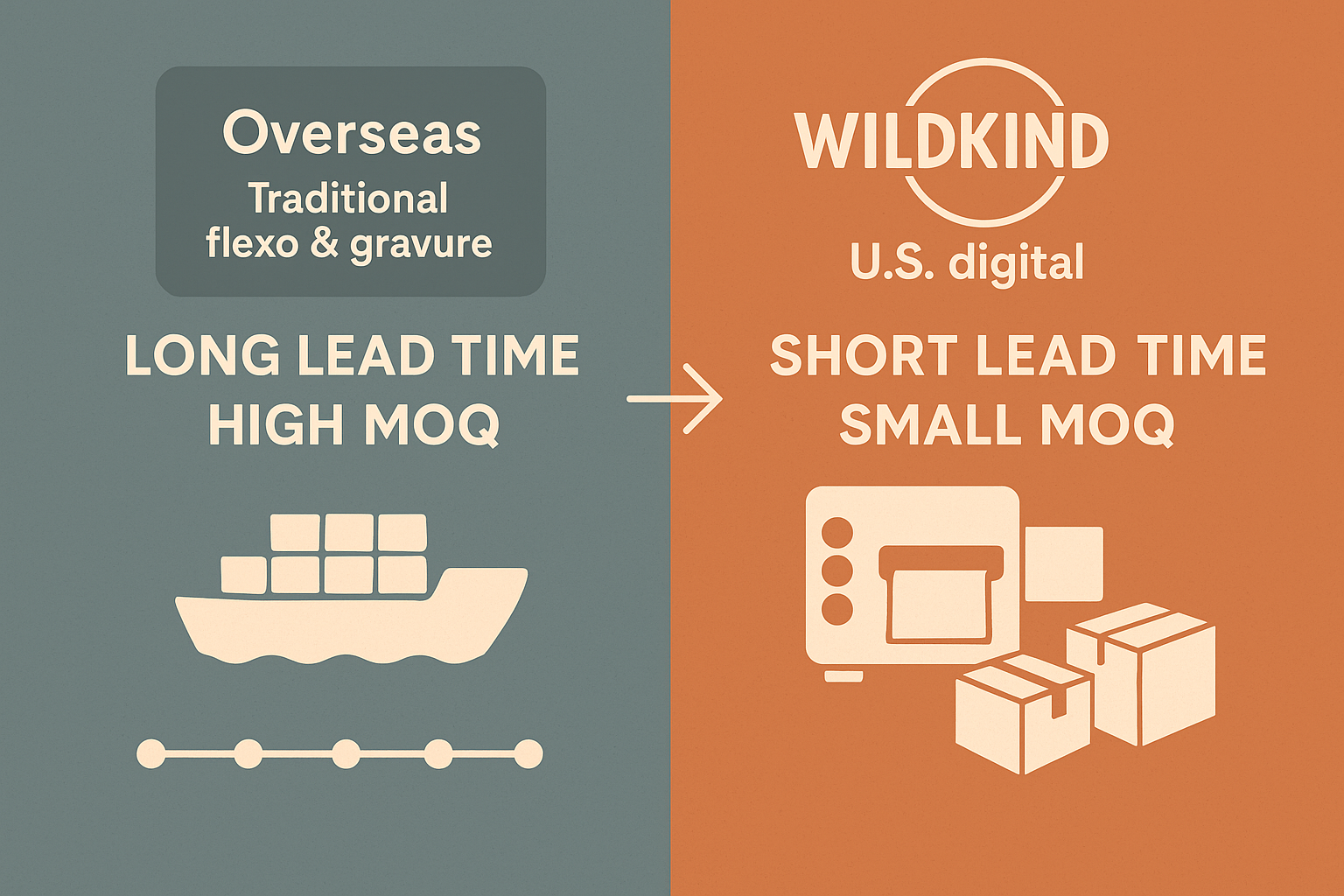

III. Because You Love Huge Minimum Orders & Long Lead Times

You don’t like being nimble. You don’t like small runs. You’d rather lock yourself into massive orders and wait months for delivery. Perfect—because that’s exactly what traditional packaging gives you.

Most conventional suppliers—especially those using flexographic or gravure printing overseas—require huge MOQs and long lead times. You’re talking 10–12 weeks (plus shipping), and that’s before you even factor in tariffs or supply chain hiccups.

But compostable packaging—at least the way WildKind Packaging does it—breaks that mold. Thanks to digital manufacturing here in the U.S., you can order small MOQs with short lead times (often as little as 10 days for smaller runs, 20 for larger).

So if what you really want is inflexibility, overseas headaches, and slow delivery, then by all means—don’t switch.

“WildKind Packaging breaks the old supply chain model with short lead times and small MOQs.”

IV. Because Your Brand Is Not Ready to Lead the Packaging Revolution

Leading is hard. You’ll need to educate customers, change internal processes, possibly invest in new suppliers, and new certifications. Maybe your risk tolerance is low. That’s fine—as long as you’re okay with being seen as behind the curve.

Consumers, especially in well-informed demographics, increasingly expect sustainable packaging. If your brand refuses to adapt, you risk being the one criticized, bypassed, or even penalized.

V. Because You Enjoy Destroying Your Customer’s Health

Let’s get real: a huge part of the harm of non-compostable packaging comes from chemical leaching, microplastics, PFAS, coatings, inks, etc. By sticking with conventional plastics or non-certified materials, you are (passively) accepting these risks.

Compostable packaging that is properly certified (e.g. BPI, ASTM D6400, EN 13432) tends to mitigate a lot of those concerns—if you choose wisely. Not doing so is like choosing to ignore toxins because they aren’t visible yet. WildKind Packaging only uses certified, food-safe compostable films designed to protect products without harming your customers.

VI. Because You Want to Rob Future Generations of the Environment

Pollution, climate change, overflowing landfills, degraded soil—these aren’t just abstract. Packaging waste plays a major role. Not adopting compostable solutions means contributing to all that.

Compostables, when processed correctly, feed back nutrients, reduce plastic waste, and support healthier ecosystems. With WildKind’s plant-based, compostable materials, your packaging doesn’t rob tomorrow—it invests in it.

VII. Because You Think It’s Expensive & Hard (You’re Not Wrong… but…)

Yes: Compostable packaging often costs more up front. Yes: sourcing certified materials, dealing with the supply chain, verifying compostability, educating packaging engineers, printers, etc., can be messy.

But the cost curve is shifting:

- As demand increases, scale improves, and materials and processes become more efficient.

- Certifications, standards, and logistics are being streamlined.

- Regulatory incentives and avoided fees (EPR, penalties) often offset many of those costs in the medium term.

And thanks to WildKind’s flexible runs, U.S.-based production, and smaller MOQs, brands can try compostables without breaking budgets—or waiting months for delivery.

VIII. Because “Safe” Today Might Mean Sorry Tomorrow

You’re comfortable with the status quo because “nothing bad has happened yet.” That mindset is great—until a regulation, retailer, or rival blindsides you.

- States are already enforcing Extended Producer Responsibility (EPR) laws compelling companies to redesign packaging, report sustainability data, and shoulder end-of-life waste costs. Brands that didn’t prepare are now scrambling. (PwC)

- Exporters are being caught off guard by new rules overseas—minimum recycled content, bans on certain plastics, and even stricter labeling. If you’re sending product abroad (or hope to), ignoring those shifts isn’t just risky—it’s expensive. (USAEDC)

- Regulations tightening on packaging chemicals (PFAS, heavy metals, plasticizers) mean that materials you used “last year without complaint” may no longer be acceptable. Companies that didn’t take steps early are now facing redesign costs, certification delays, or worse. (Manufacturing Dive)

So if you like being behind the curve—facing emergency fixes, panic redesigns, or losing contracts because you couldn’t prove your packaging meets current rules—then by all means, keep doing what you’re doing.

Because the moment you felt “safe,” the landscape was already shifting. And when everyone else is ready, being “not ready” won’t feel safe—it’ll feel like regret.

IX. What You Might Think: “But we’ll just stick with the status quo…”

- “Consumers don’t care that much.” Maybe. But the ones who do are often influential and vocal.

- “Compostable options don’t perform as well.” Historically true in some cases, but many newer materials and designs match or approach performance if properly engineered.

- “The cost premium is too high.” Costs are dropping. And avoided costs (fees, reputational damage, losing market share) often exceed the premium.

- “There’s no infrastructure for composting in many places.” True in parts—but infrastructure is growing. Also, even where industrial composting isn’t available, correctly certified compostables can reduce contamination and environmental harm, plus you can promote take-back or collection programs.

FAQs About Compostable Packaging

- Is compostable packaging really better for the environment?

Yes—when properly certified and disposed of, compostable packaging reduces plastic waste, supports soil health, and lowers pollution compared to conventional packaging. - What’s the difference between compostable and biodegradable packaging?

Compostable packaging must break down under specific composting conditions and leave no toxic residue. “Biodegradable” simply means it will break down eventually—sometimes in decades. - Is compostable packaging more expensive?

Upfront, often yes. But costs are coming down with scale, and savings on EPR fees, shipping, and avoided penalties can make compostables cost-competitive. - Are there supply chain advantages to compostable packaging?

Yes, especially when using WildKind Packaging’s U.S.-based digital manufacturing. That means shorter lead times, smaller MOQs, and fewer overseas risks like tariffs and shipping delays. - Can compostable packaging protect food and products as well as plastic?

Modern compostable films and laminates are designed to match performance in barrier protection, shelf life, and durability. Certification ensures safety and performance. - What if composting facilities aren’t available in my area?

Even without industrial composting, certified compostables reduce harm compared to plastics and can still play a role in brand storytelling, consumer education, and future-proofing your business.

“The moment you felt safe, the packaging landscape was already shifting.”

X. Why You Should Do Compostable Packaging

Look, resisting compostable packaging in 2025 offers short-term comfort but long-term risk. The regulatory clock is ticking. Consumer expectations are rising. Supply chains are adapting. Brands that lead now will grab trust, differentiation, and avoid penalties.

If you’re serious: begin with small steps—choose certified materials, test a product line, partner with a reliable supplier, measure the carbon or waste savings, and use that story in your marketing.

At WildKind Packaging, we make that leap easier. With certified compostable films, U.S.-based digital manufacturing, small MOQs, and short lead times, we’re here to help brands lead the packaging revolution.

Because when everyone else is catching up, you want to be the one telling customers: yes, we did it. Not the one scrambling to catch up.

Login and Registration Form